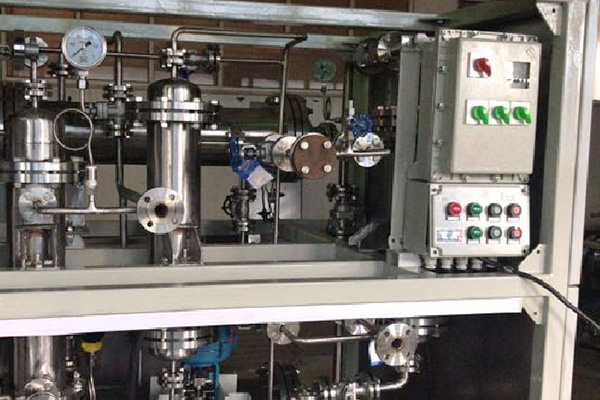

Based on module unit technology, to define the price and supply date of products, to provide customers with a customized set of systems

Preprocessing unit The main purpose of pretreatment is to make the solvent raw material meet the clean requirements of the membrane module. Generally using filtration, vaporization, neutralization, steam compression and other ways, can be selected according to the nature of customer raw materials. | Thermal energy reuse unit After dehydration, the product has high thermal taste and can be used for feed preheating or coupling other process units. The steam through the membrane module can be recovered and reused by heat pump system. | |

Vacuum condensation unit In order to meet the requirements of dehydration, it is necessary to reduce the partial pressure of water vapor on the osmotic side of the membrane module. Vacuum unit or carrier gas purging unit are suggested to use, and then the osmotic solution is obtained by deep condensation or freezing. | Security filter It is an independent development of patented products. It can avoid the pollution of the core materials of the membrane assembly, improve its function and stability, and prolong the service life of the membrane tube. |

Selection Table of complete sets of equipment for ethanol dehydration and refining

capacity\Type\Rate of water content\Dehydration target | Target: water content<0.1% | Target: water content<100ppm |  | |||||

| Initial watercontent % | Initial watercontent % | |||||||

| 10 | 5 | 3 | 10 | 5 | 0.5 | |||

| Capacity t/year | 1000 | |||||||

| 2000 | ||||||||

| 3000 | ||||||||

| 4000 | ||||||||

| 5000 | ||||||||

| 6000 | ||||||||

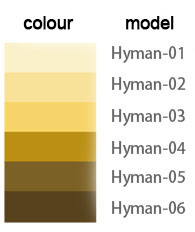

| model | Footprint/m | Price/ 10,000 Yuan |

| Hymae-01 | ~3×3×2 | |

| Hymae-02 | ~4×3×3 | |

| Hymae-03 | ~6×4×3 | |

| Hymae-04 | ~6×5×4 | |

| Hymae-05 | ~7×5×4 | |

| Hymae-06 | ~8×6×5 |