The company's own research and development of ONPS? process (On-site NMP Purification System) can be used for lithium industry NMP solvent recovery and purification. The whole system has no tower equipment, integrates the waste liquid treatment system to realize zero discharge, the whole system runs automatically, can choose the cycle operation and the continuous treatment mode, the NMP purity of the product is more than 99.9%, the water content is less than 50ppm, and the recovery rate is more than 99%.

| ● Small area, high integration, can be fully driven by electricity; | ● High efficiency dehydration, one way to reach 5~200ppm index; |

| ● Zero emissions, no worries about environmental protection; | ● Quick start and stop, full automatic operation; |

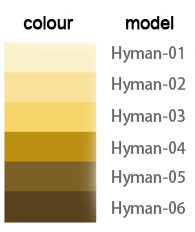

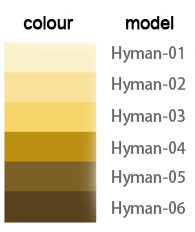

Selection Table of Refining Equipment for NMP Zeolite membrane Refining

Capacity\Type\Water content\Dehydration target | Target: Water content<50ppm |  |

| Initial water content |

| 20 | 15 | 10 | 5 | 3 |

Capacity

t/year | 1000 | | | | | |

| 2000 | | | | | |

| 3000 | | | | | |

| 4000 | | | | | |

| 5000 | | | | | |

| 6000 | | | | | |

| 7000 | | | | | |

| 8000 | | | | | |

| 9000 | | | | | |

| 10000 | | | | | |

| model | Footprint/m | Price/ 10,000 Yuan |

| Hyman-01 | ~3×3×2 | |

| Hyman-02 | ~4×3×3 | |

| Hyman-03 | ~6×4×3 | |

| Hyman-04 | ~6×5×4 | |

| Hyman-05 | ~7×5×4 | |

| Hyman-06 | ~8×6×5 | |

Technical index ofi-propanol ultra-pure reagent

| Name | guarantee reagent | chromatographic pure | electron level |

| Preparation stage | liquid chromatography | agricultural residue level |

| i-propanolcontent(GC)�,ω% | ≥99.8 | ≥99.9 | 99.9 | ≥99.9 | ≥99.9 |

| water content(H2O),ω% | ≤0.15 | ≤0.10 | ≤0.10 | ≤0.10 | ≤0.005 |

| density(20℃)�����,p/(g/mL) | 0.784-0.786 | 0.784-0.786 | 0.784-0.786 | 0.784-0.786 | 0.785-0.786 |

| evaporites,ω% | ≤0.0005 | ≤0.001 | ≤0.0005 | ≤0.0005 | ≤0.0001 |

Acidity(In terms of h+)/(mmol/g) | ≤0.0003 | ≤0.0003 | ≤0.0003 | ≤0.0003 | ≤0.0001 |

| Reduction of potassium permanganate | qualified | --- | --- | --- | --- |

Carbide | qualified | --- | --- | --- | --- |

| oxo-compound�����,ω% | ≤0.005 | --- | --- | --- | --- |

| Methanol,ω% | ≤0.1 | --- | --- | --- | --- |

| Iron ����,ω% | ≤0.00001 | --- | --- | --- | ≤0.0000001 |

Technical index of acetonitrile ultrapure reagent

| Name | guarantee reagent | chromatographic pure | electron level |

| Preparation stage | liquid chromatography | agricultural residue level |

| CH3CN(GC),ω% | ≥99.80 | ≥99.90 | ≥99.90 | ≥99.90 | ≥99.90 |

| water content(H2O)�����,ω% | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.02 | ≤0.02 |

| density(20℃)����,ρ/(g/mL) | 0.782-0.785 | 0.782-0.785 | 0.782-0.785 | 0.782-0.785 | 0.782-0.785 |

| evaporites | ≤0.001 | ≤0.001 | ≤0.0005 | ≤0.0005 | ≤0.0005 |

| Reduction of potassium permanganate | 合格 | | | | --- |

| Acidity(In terms of H+)/(mmol/g) | ≤0.001 | ≤0.0005 | ≤0.0004 | ≤0.0004 | ≤0.0004 |

| Alkalinity(In terms of OH-)/(mmol/g) | ≤0.001 | ≤0.0002 | ≤0.0002 | ≤0.0002 | ≤0.0002 |

Technical index of alcohol ultrapure reagent

| Name | guarantee reagent | chromatographic pure | electron level |

| Preparation stage | liquid chromatography | agricultural residue level |

| CH3CH2OH,ω% | ≥99.90 | ≥99.80 | ≥99.80 | ≥99.80 | ≥99.80 |

| water content(H2O)��,ω% | ≤0.2 | ≤0.2 | ≤0.15 | ≤0.15 | ≤0.2 |

| density(20℃�,ρ/(g/mL) | 0.789-0.791 | 0.789-0.793 | 0.789-0.794 | 0.789-0.795 | 0.789-0.792 |

| evaporites | ≤0.0005 | ≤0.0005 | ≤0.0005 | ≤0.0005 | ≤0.0005 |

| Acidity(In terms of h+)/(mmol/g) | ≤0.02 | ≤0.0004 | ≤0.0004 | ≤0.0004 | ≤0.0002 |

| Alkalinity(In terms of OH-)/(mmol/g) | ≤0.005 | | ≤0.0001 | ≤0.0001 | ≤0.00005 |

| Methanol,ω% | ≤0.02 | --- | --- | --- | ≤0.02 |

| i-propanol��,ω% | ≤0.003 | --- | --- | --- | ≤0.003 |

| Carbide | qualified | --- | --- | --- | qualified |

| Reduction of potassium permanganate����,ω% | ≤0.00025 | --- | --- | --- | ≤0.00025 |